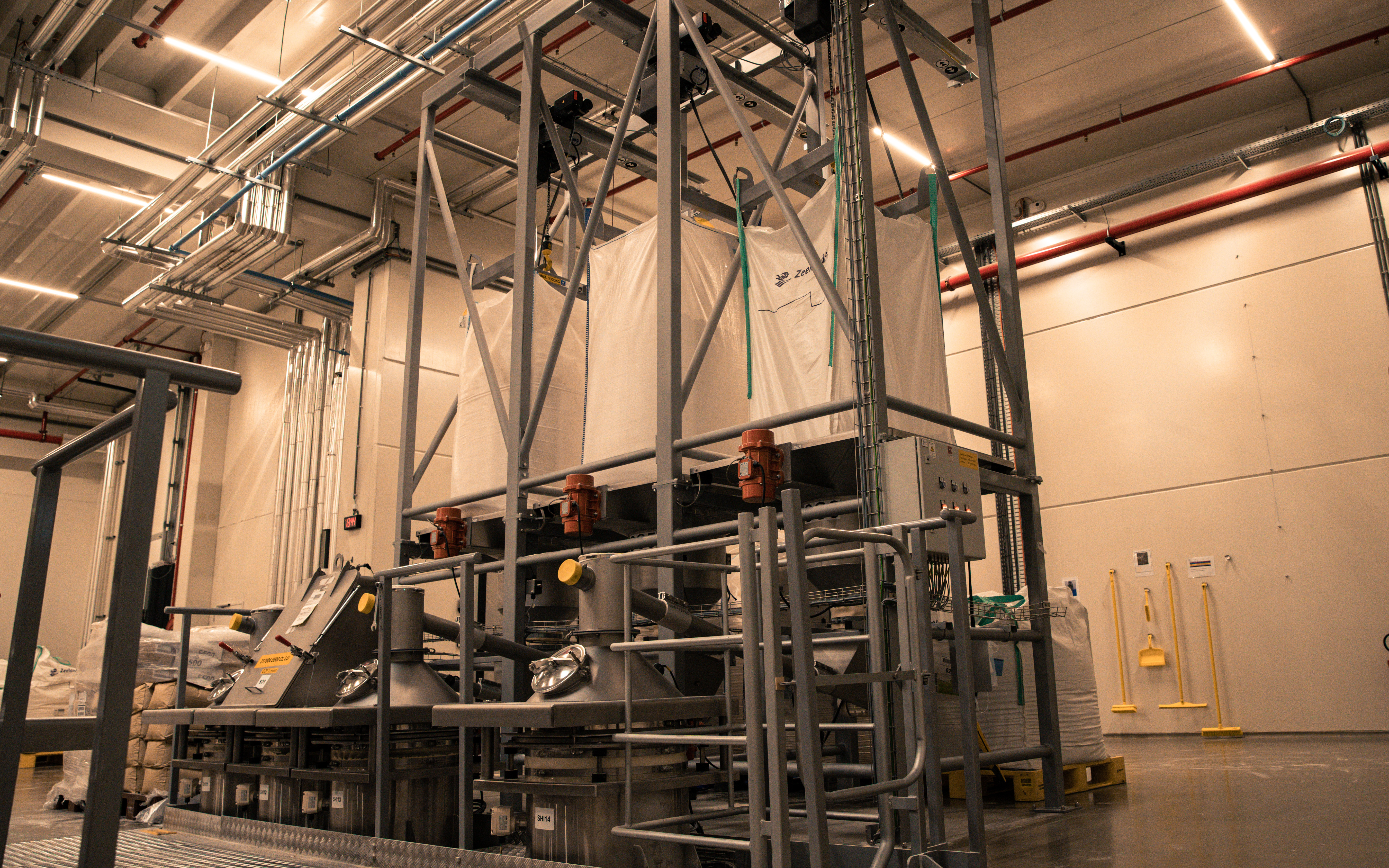

Big Bag unloading station

Enhance Your Ingredient Handling with Spiromatic's Big Bag Unloading Stations

Efficiently discharge a wide range of raw materials, from flour, sugar, and salt to semolina and cacao powder, with Spiromatic's advanced Big Bag Unloading Stations. As the trend towards large-scale ingredient supply in big bags continues to grow, our modular unloading stations are here to meet your specific needs, whether budget-driven or tailored to your exact requirements. Choose between coated or stainless steel options, each crafted for durability and performance.

Key Benefits of Spiromatic's Big Bag Unloading Stations:

- Effortless Handling: Our automatic hoist-equipped stations minimize manual labor, enhancing efficiency and safety.

- Versatile Discharging: Experience the flexibility of bottom or side discharging to suit your production process.

- Clean and Contamination-Free: Optional high-end extraction devices ensure dust-free, contamination-free big bag openings, safeguarding the integrity of your ingredients.

- Precision Dosing: Achieve precise ingredient dosing, even in small quantities, with ease.

- Seamless Integration: These stations seamlessly integrate with various conveying systems, enhancing your production line's efficiency.

- Free-Flow Extraction: Experience smooth and consistent ingredient flow for uninterrupted production.

- Ergonomic Design: Shorten setup times and ensure safer operations with our ergonomic design principles.

Key Technical Parameters:

- Handling capacity of big bags up to an impressive 1250 kg.

- Compact footprint with a typical system size of 1400mm x 1500mm.

At Spiromatic, we're committed to delivering innovative solutions that optimize your ingredient handling, improve efficiency, and elevate the quality of your products. Choose Spiromatic's Big Bag Unloading Stations for a seamless and efficient ingredient handling process. Elevate your production with us today.